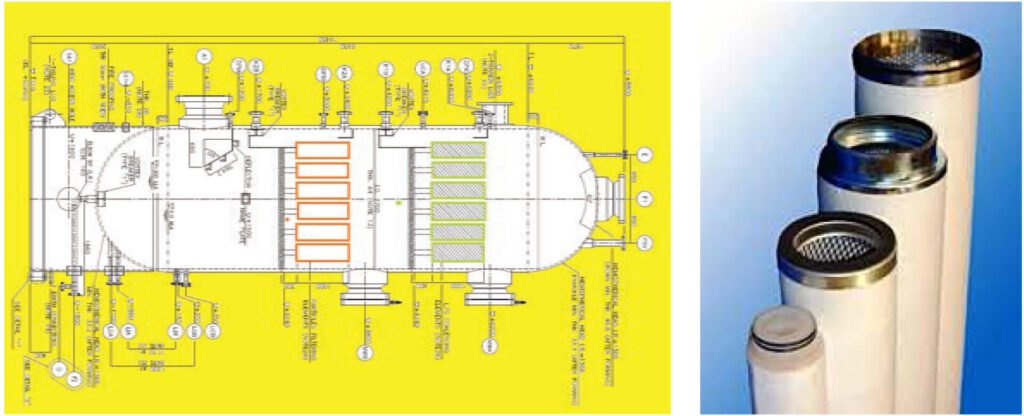

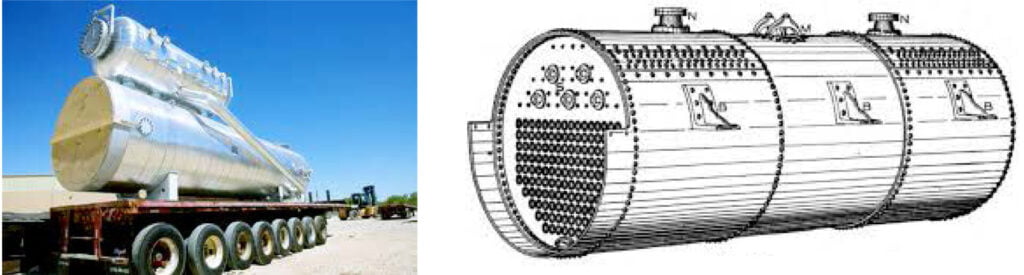

NOJOOMALDUHA LCC Co. is an UAE EPC contractor for desing and fabrication of the sampling cooler.

This equipment is a heat exchanger for cooling of boiler water , steam , process samples such as crude oil, gas and any chemical fluid .

The following equipment could be also supplied in order to complete the sampling equipment:

Cabin Sampling

Pressure Reducer & Safety Valve

Thermometer & Pressure Indicator

Flow Indicator & Flow Meter

Analyzer & Transmitter

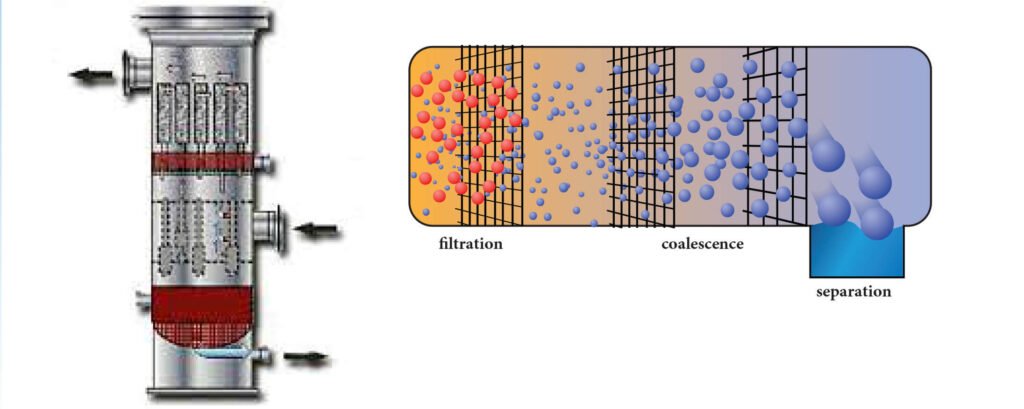

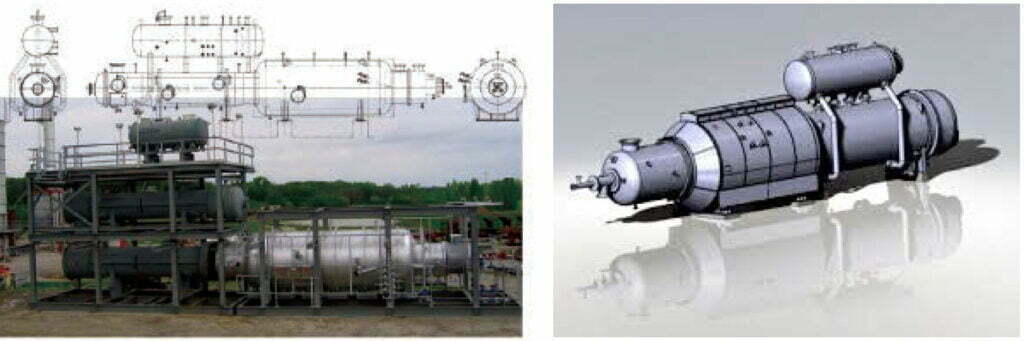

NOJOOMALDUHA LCC is the UAE EPC contractor for desing and fabrication of the Gas Filter Coalescer. Technology consists of solids filtration, coalescence and separation.

Principal Of Operation:

The first step is to remove the solid contaminants using a cartridge filter. Solids can increase the stability of an emulsion and can plug the coalescer, thereby reducing its efficiency. Removing solids will precondition the fluid for optimum coalescer performance. During coalescence, the droplets to be separated from the bulk fluid are captured by the high-performance coalescer medium. The droplets then move through the coalescer media (with progressively larger pores) and are coalesced to form larger droplets. Lastly, the large droplets are released. After the droplets are released from the media, the phases are separated either by phase separators or by gravity in the settling zone.

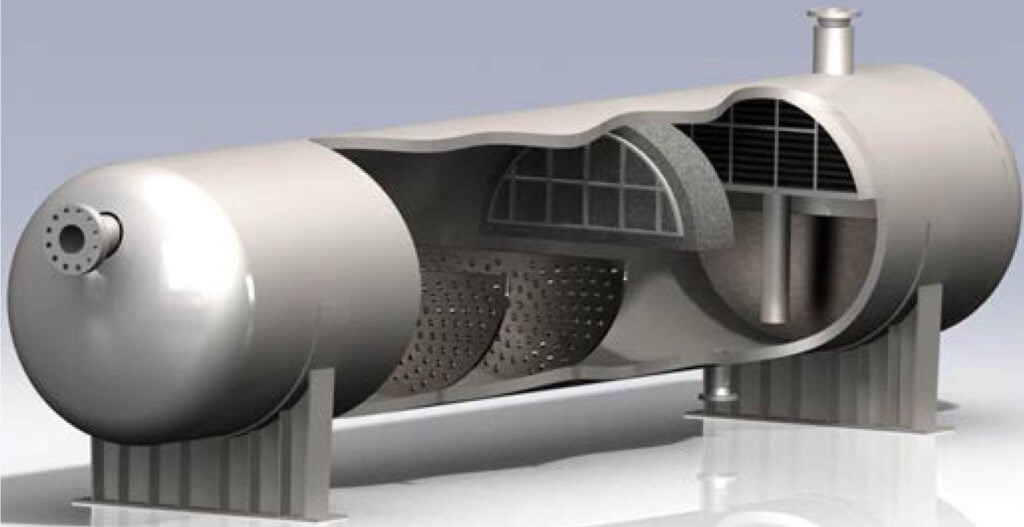

NOJOOMALDUHA LCC Co. is an UAE EPC contractor for desing and fabrication of the Three Phase Separator. The three phase separator is designed to separate a measure water, gas and oil rates. The separators are equipment with internal components that

facilitate and improve the phase separation and with complete instrumentation and control valve that allows to provide customers with accurate information concerning the well performance of oil wells.

Features:

High pressure separators with best cladding

Min Water ppm on oil/ min. ppm oil in waste water

Sand removal to provide best maintenance period

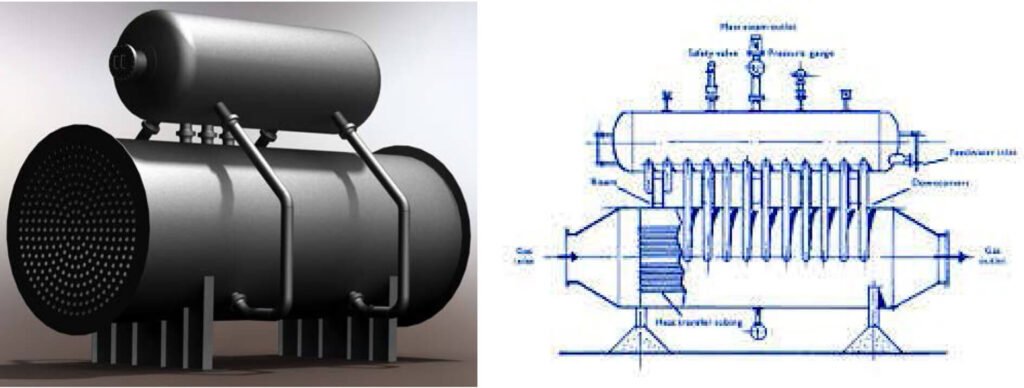

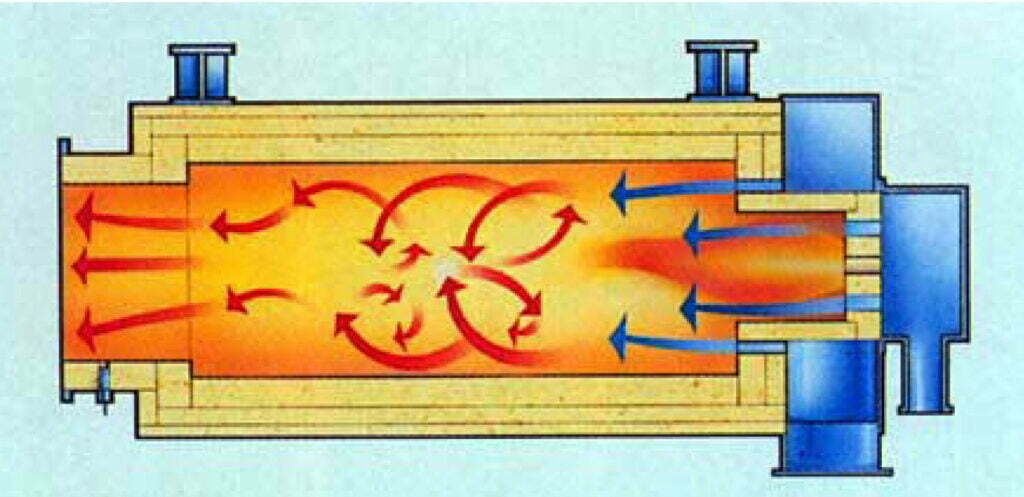

NOJOOMALDUHA LCC Co. is an UAE EPC contractor for desing and fabrication of the Waste Heat Boiler (Fire Tube) . This type of Boiler is also known as heat recovery boiler or process gas cooler. This plant takes hot flue gas and produce LP or MP steam up to 20bar for the follow- ing plant:

Sulfur recovery unit

Incinerators

Small gas turbine

Furnaces

Advantage:

Heat recovering from high temperature exhausts flue gas

Producing LP or MP steam up to 20bar with high purity

Reducing flue gas temperature in stack

Reducing refractory cost of stack

NOJOOMALDUHA LCC Co. is an UAE EPC contractor for desing and fabrication of the Incinerator.

Gas incinerators are used to burn hazard waste gases completely. It could be replaced by flare system to burn the flare gas completely.

Incinerator has a capability to join to HRSG (Heat Recovery Steam Generator) to produce steam up to 20 bar.

Advantage:

High combustion efficiency

Low emission

Produce steam up to 20 bar

Reduce fuel cost vs. steam generation

Applications:

Desalting units

Gas refineries

Tail gas unit treatment

Oil refineries

Petrochemical plants

Flare system

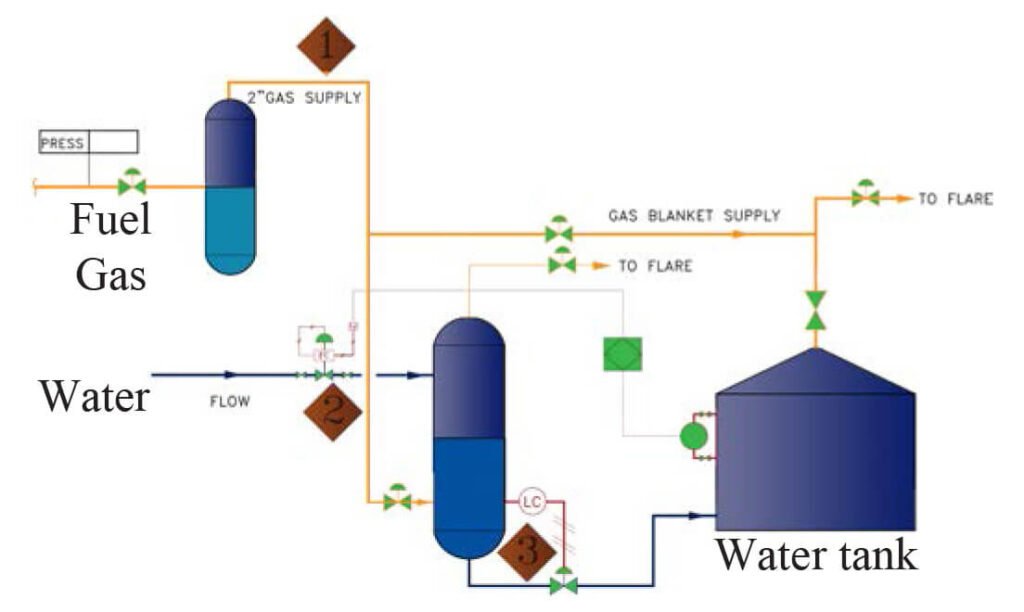

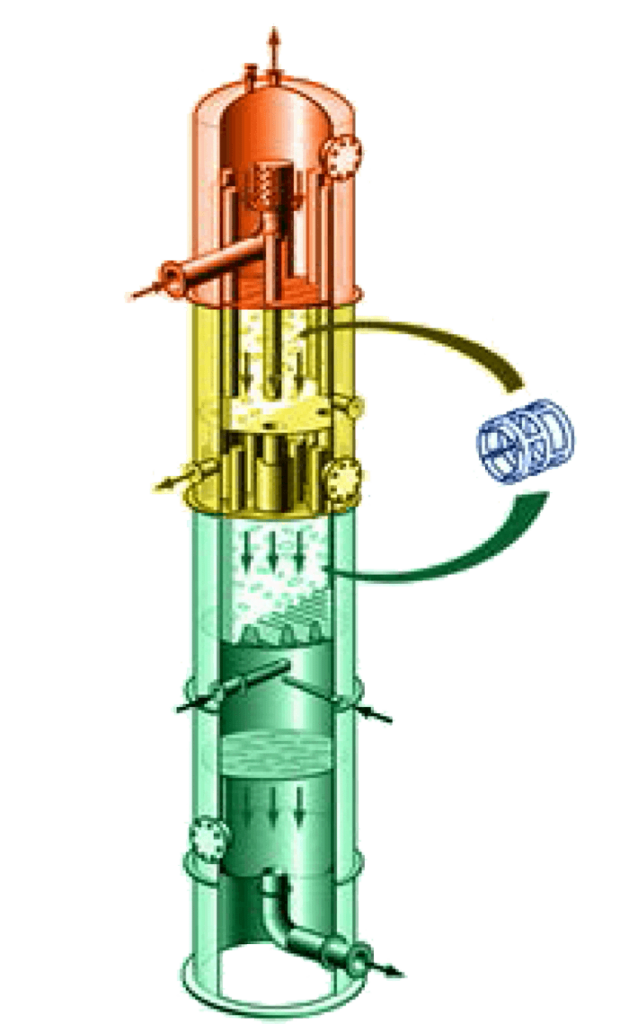

NOJOOMALDUHA LCC Co. is an UAE EPC contractor for desing and fabrication of the Trace Gas Stripping Deaerator. This system combines vacuum stripping and inert gas stripping to offer a unit that operates with the mass transfer process being assisted by a small quantity of inert gas admitted into the deaerator column.

NOJOOMALDUHA LCC Co. is an UAE EPC contractor for desing and fabricatoin of theVacuum Deaerator. Vacuum Deaerator is for cold water systems 10-40 ˚C .The make-up water, is fed to the upper section of the tower. Dearator tower has 3 sections (best model). The vacuum pump creates the necessary vacuum so that the make-up water boils in lower temperature. In Vacuum condition, the oxygen is liberated and removed by means of the vacuum pump. At the deaerator tank oxygen scavenger is added to remove the residual dissolved gases.

Function:

Water injection in oil and gas reservoirs

Water providing for desalting crude oil

Water providing for water sweetening plant

Water providing for utility consumptions

NOJOOMALDUHA LCC is an UAE EPC contractor for desing and fabrication of the Steam Deaer-ator. Deaerator (thermal or pressurized) is a Degasification device that is used for the removal of air and other dissolved gases from the feed water to steam-generating boilers by heating steam.

Deaerators are designed to remove oxygen down to levels of 7 ppb by weight or less as well as essentially eliminating carbon dioxide.

Spray -Tray-Type Deaerator

Includes a vertical tower (or horizontal for capacity more than 400Ton/hr) which minimizes the amount of vent steam .

Spray-Type Deaerator

Does not Include a tower .This type is an economic system .

Packing-Type Deaerator

Advantages:

- Prevent corrosion & thermal stress of boiler;

- Increase thermal efficiency;

- Provide NPSH for Feed water pump;

- Storage of the Deaerated boiler feed (5min. to 20 min.).